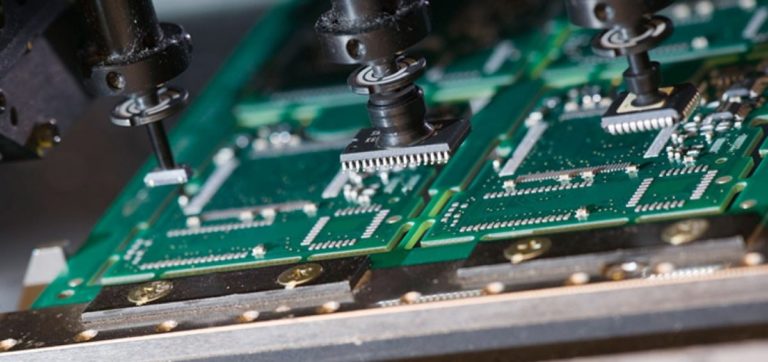

In this article, we will be acknowledging our readers about some of the most important parts of the China pcb prototyping process in detail. One of the easiest ways as per the majority of pcb prototype specialists is to work with an expert pcb prototype partner. There are several companies in China that will assist you flawlessly in this process and will guide you through every step of the entire process.

A number of decades has passed since the experiences of the industry as well as the high levels of customer service evolved. There are many China pcb manufacturers that are ideally suited to guide you through each of the important step involved in the pcb prototype generating process.

Keeping the China pcb prototyping process simple and easy-to-digest, we will start with a schematic. A schematic, in simple words, is a basic blueprint of the circuit. This blueprint is responsible for laying out all the present components as well as their linkage which each other. Also, you can craft a schematic by making use of a basic circuit software. Some of the softwares will be able to automatically convert those schematics into a perfect China pcb file.

Next step is the optimization of the design. While designing a China pcb or a pcb prototype, there are several things that can be done for the purpose of design optimization. The best thing to do is identify various parts of your circuit and keep those parts united together. Also, seeking to ensure that the electric current’s path is as linear as it can be as well as that each circuit’s section is supplied with adequate power is important.

Working with a pcb prototype, when you reach at the stage of examination, another important step to be taken is; think about the interaction between the China pcb and the final product.

You may also have interacted with the term Multilayer China pcb. Keeping it brief, large circuits can be hard to fit on a China pcb which is single layered. This is because it is much hard to route the traces without letting them to intersect. In such cases, double or multi-layered pcb prototype having copper-plated holes that are playing as a connection between the above and the lower layers will be ideal.

If you are willing to submit your design to an expert pcb prototype designer, there are a few things or information that needs to be gathered about your China pcb design. It may include:

- Thickness of the board

- Number of layers needed

- Thickness and weight of the copper

- Minimum spacing and tracing needed

- Minimum size of the hole

- Surface finish

- Color and the Soldermask

- Drill file NC Excellon

- Drill file tool list

- Color and Silkscreen legend

Also, the design files can be submitted to expert pcb prototype designers using a wide variety of software packages. Many of the China pcb companies convert files to RS-247X. If your selected company is doing the same, it is important to include the following elements; positive Gerber layers, a drill tool list and information on the aperture, an NC Excellon drill file, as well as solder mask and silkscreen.

ChinaPCBOne Technology LTD. is the author of this article on pcb prototype. Find more information, about China pcb.

Comments are closed.